Thanks for your continued interest and comments fellas

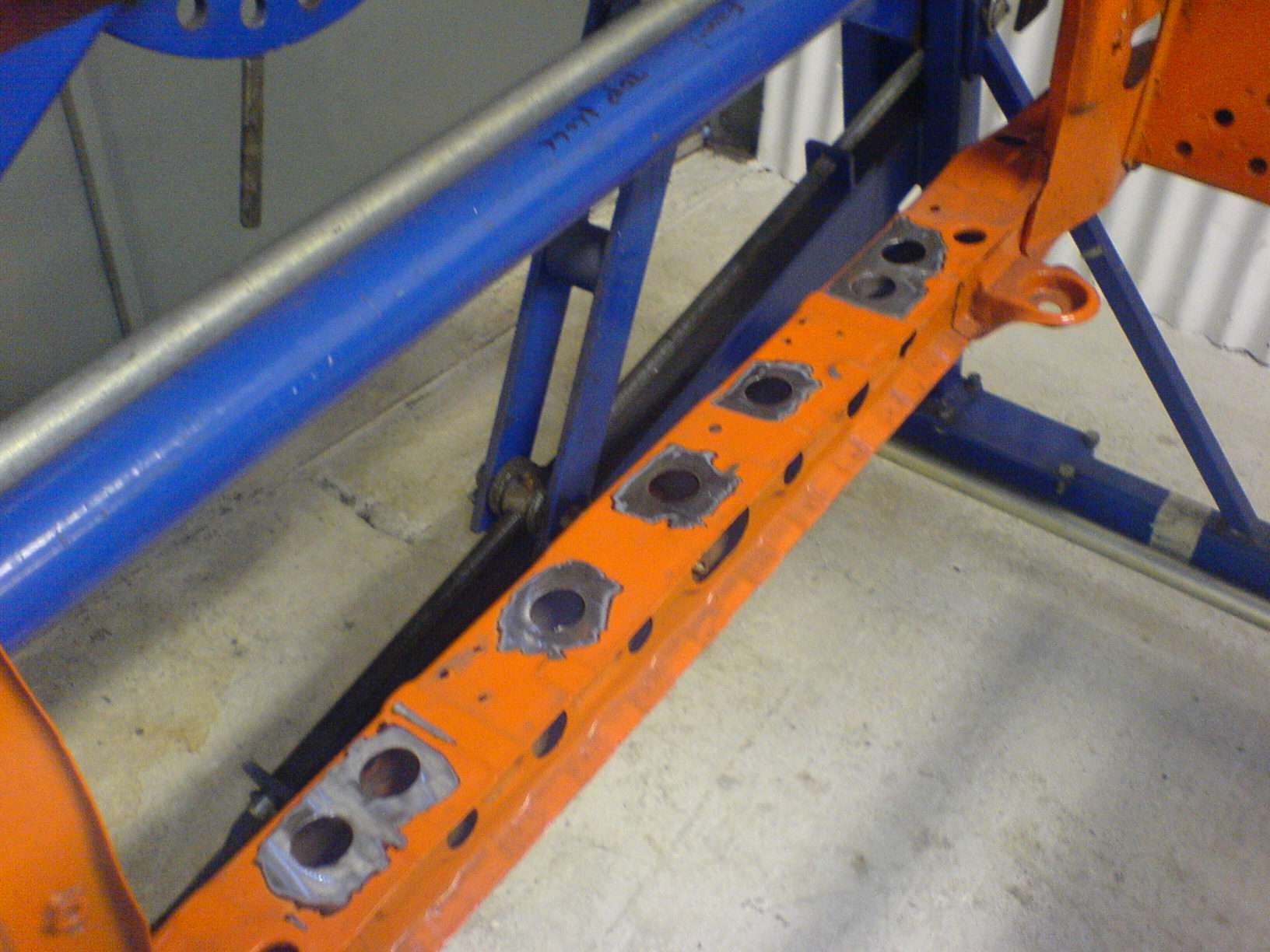

Still a very long way to go in the big scheme of things but we're now on the home straight as far as 'shell prep goes.

Got a few more pics which I'll post up in a mo and then I'm up to give the car a final going over to make sure we've got everything covered before it goes for paint later in the week.

In reply to some of your posts - BTW don't be offended if I don't reply to yours personally, all comments are really welcomed and I'll always do my best to cover any questions asked.

Dom -

Yeah you certainly can't fault the workmanship that's for sure....but then again I knew that from the start having seen plenty of their "everyday" stuff.

Boot floor is perfect, exactly how we discussed it...in fact it's probably even better

Dave -

Thanks mate, as I said, it's got a long way to go but I am not going to rush any part of the build. Originally intended to be hitting the track with it later this year for testing and then racing next year but I've decided not to give myself a deadline. If I had unlimited resources then it would be easy to get it finished in less time but each part of the process needs to be budgeted for before I can move on to the next.

I have plenty to get on with already but TBH I've been too busy with customer cars and planning the next stages.

The engine which was fully built and ran well way back at the end of last year is currently fully stripped and back in sealed crates ready for the build back up again. I've had a few more mad ideas which I'm currently exploring before starting the rebuild again though....doubt I'll use them but it's only my time I'm wasting if I don't

Also got the gearbox build to get done at some point, thankfully that is just a pretty straightforward build - M2F5 with 4.64 final drive and Kazz 1.5way plate diff - may or may not run a cooler on the box as the temps on the old M2B4 were ridiculous during long sessions.

Bri -

Damn right it's strong, the cage is only part of the strength. The way it's being integrated with the shell adds lots to the overall strength of the structure not to mention the sheer amount of seam welding work which has been done too.

Re- RWD and S2k engine.

Whatever engine you decided to run if you were going to go RWD would have been a bucket load of work. Nothing that can't be done of course but again if I had of gone RWD with it I wouldn't have used the S2k F20c for sure.......even though I do just so happen to have one lying around in my workshop

dlongmu -

Yeah I know it's not impossible to run RWD with the H but as a practicality there are many many much better options out there. Regardless of that, the car was realistically always going to stay FWD....after all that's what Preludes are. Think along the lines of a budget Prelude Super Tourer and that's what I'm after

Maxx -

You are kidding right?

I don't think I've ever seen anybody that's been as thorough with a Prelude as you have with your project. Your attention to detail and insistence on everything being right goes over what most people would even think of. It's all for very different reasons of course but I can see from your thread that you won't accept second best at all

Steve -

Might be able to sort something out with regards to those seat mounts for you. Leave it with me and I'll let you know.

Nathan -

LOL I very nearly almost typed "Here's where Nathan says I told you so"

To be fair to the guys, they were happy enough to TiG it all if I'd demanded it...we discussed it one evening while I was up with the car and it was basically decided to keep things simple and go with the mighty MiG for the seam work. Little bit heavier but a whole lot easier and of course a fair bit cheaper. Most of it is out of sight anyway but even having said that their standards of welding are still top notch.

Right lets get a few more images up

Rich